Manufacturing Use Case - UK Based Vehicle Manufacturer

23 February 2021

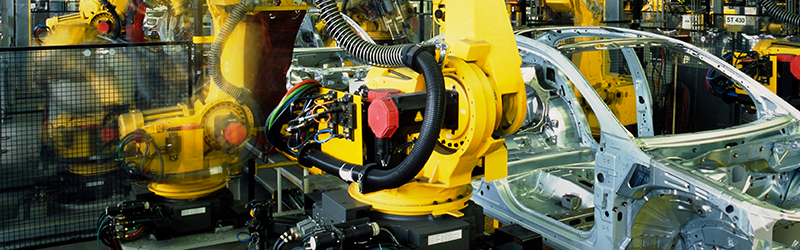

With manufacturing excellence very

much at the forefront of this operation, intelligent technologies play a key

part in securing this company’s vision.

Not only do CCTV systems play a fundamental part in their ability

to secure their premises and assets, but also to support streamlined processes,

cost efficiencies and most importantly, manufacturing excellence.

The initial requirement for CCTV was to provide additional

coverage within their headquarters and main production line. The site was

utilising an existing analogue system and whilst the company had been satisfied

with the coverage, they were now looking to extend the network of existing cameras

to provide high-definition surveillance across additional areas of the site.

The requirement for CCTV was to fulfil multiple objectives. Not

only was the system looking to monitor both the manufacturing process and

personnel movements, but it was also needed to provide advanced analytical

capabilities to support existing process improvements.

The

Solution

The company selected TouchStar ATC to specify, plan, install

and support a full CCTV system.

As part of the CCTV system, the company was looking for

superior analytical technology. With a vast knowledge of all third-party

security products, TouchStar’s engineering team had the training and expertise

to design the system around the company’s specific needs. Both the company and

TouchStar specified an Avigilon system, knowing that it would fulfil the

objective for quality cameras and next generation video analytics. With

TouchStar engineers fully trained on the system, a mixture of high-resolution camera’s

was specified, maintaining a minimum resolution of 8mp and range of types from

multihead through to fish eye and bullet cameras.

Results

and Benefits

The initial system was successfully deployed by TouchStar

approved installers in 2018. In the two subsequent years, the system and installation

works has been successfully audited, achieving the NSI Gold standard to provide

the reassurance that the company have invested in a quality solution.

Since the installation, the system has delivered several

cost benefits, particularly because of supporting existing process

improvements. Most notably, an ROI was achieved in a matter of weeks within the

body preparation area of the operation. The ability to monitor both this area

and other manufacturing areas within the operation has helped the company have

a better understanding of this process. With video analytics, they are now able

to effectively troubleshoot any manufacturing errors or faults more efficiently

and effectively, resulting in a much more streamlined operation and a

significant reduction in operational costs.

Not only has the system delivered a number of tangible

benefits, but it was also well received by the staff working within the site.

All staff recognised the positive impact that video analytics has had within

their working environment which has made a significant contribution to the

overall success of the system.